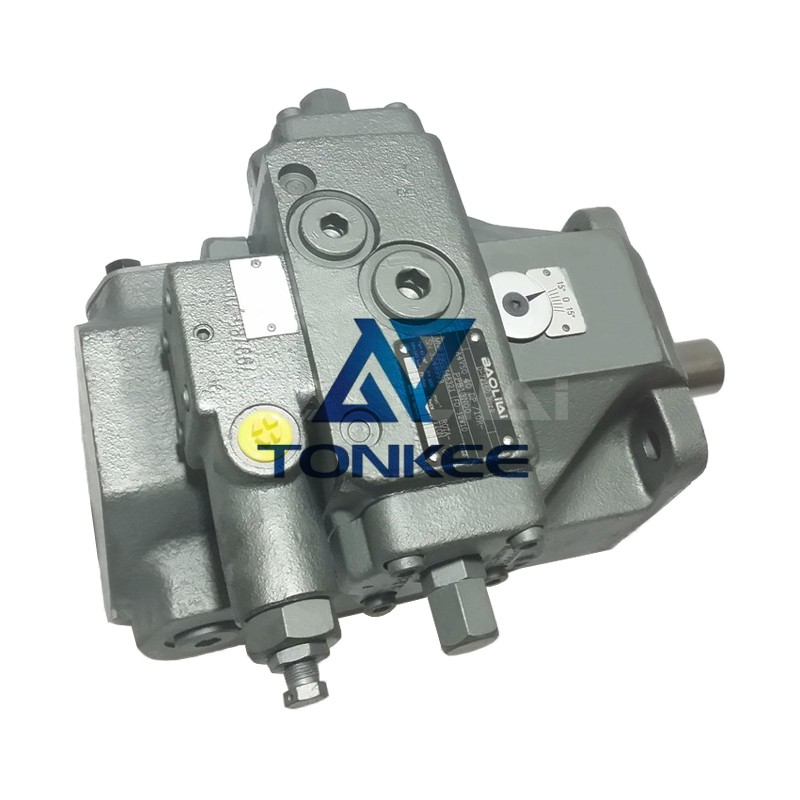

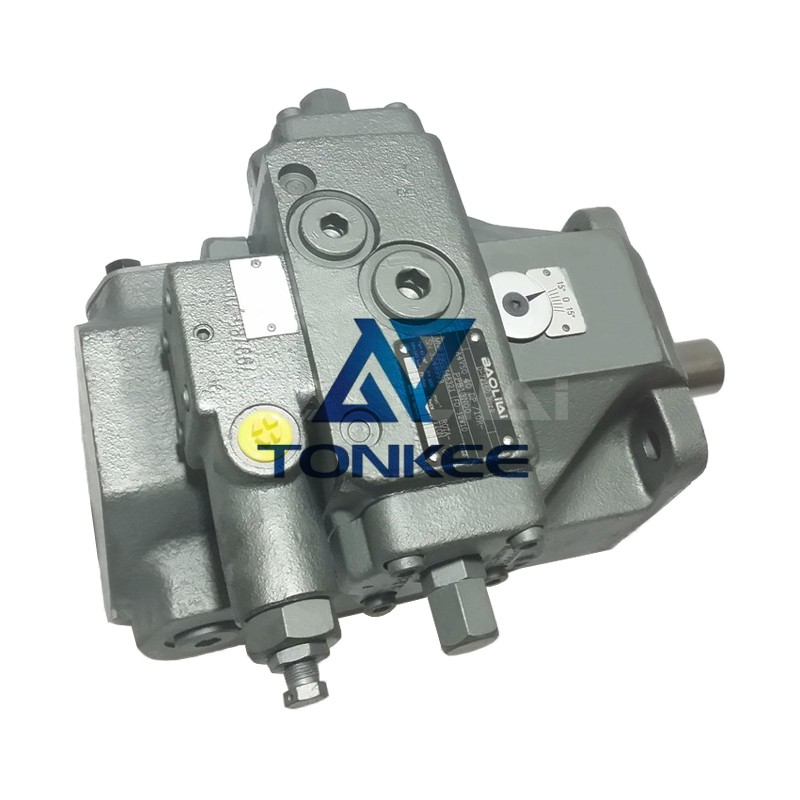

Pump Housing: The pump housing is a crucial component that encloses and protects the internal parts of the hydraulic pump.

When selecting a replacement pump housing for the AA4VSO series, it's important to ensure compatibility with the pump model and size. The material of the housing should be durable and resistant to corrosion, ensuring long-term reliability.

Cylinder Block: The cylinder block is responsible for housing the pistons and distributing hydraulic fluid within the pump. When choosing a replacement cylinder block, it's vital to consider the pump's displacement and pressure ratings. The cylinder block should match the specific model and size of the AA4VSO pump to ensure proper fitment and performance.

Pistons and Piston Rings: Pistons play a crucial role in converting hydraulic energy into mechanical power. When replacing the pistons and piston rings, it's essential to consider the material, dimensions, and surface finish. High-quality replacement pistons and rings ensure proper sealing and minimize leakage, resulting in efficient pump operation.

Valve Plate: The valve plate controls the flow of hydraulic fluid within the pump. When selecting a replacement valve plate, it's important to consider factors such as pressure rating, flow capacity, and material composition. The valve plate should match the specific model and displacement of the AA4VSO pump to ensure smooth and precise fluid control.

Shaft Seal: The shaft seal prevents leakage of hydraulic fluid along the pump's drive shaft. When choosing a replacement shaft seal, it's important to consider factors such as material compatibility, pressure rating, and temperature resistance. A high-quality shaft seal ensures proper sealing and extends the pump's service life.

Bearings: Bearings provide support and reduce friction between moving parts within the pump.

When replacing bearings in the AA4VSO series pump, it's crucial to select bearings with the correct dimensions, load capacity, and material composition. High-quality bearings ensure smooth operation and help prevent premature wear and failure.

Seals and O-rings: Seals and O-rings are essential components that prevent leakage between different sections of the pump. When selecting replacement seals and O-rings, it's important to consider the material composition, temperature resistance, and compatibility with hydraulic fluids. Properly selected seals and O-rings maintain the pump's efficiency and prevent fluid leaks.

Control Devices: The AA4VSO series pump may include various control devices such as pressure compensators, flow control valves, or proportional control valves. When replacing control devices, it's crucial to ensure compatibility with the specific model and size of the pump. The control devices should match the required pressure and flow specifications to maintain accurate system performance.

English

English português

português Русский язык

Русский язык