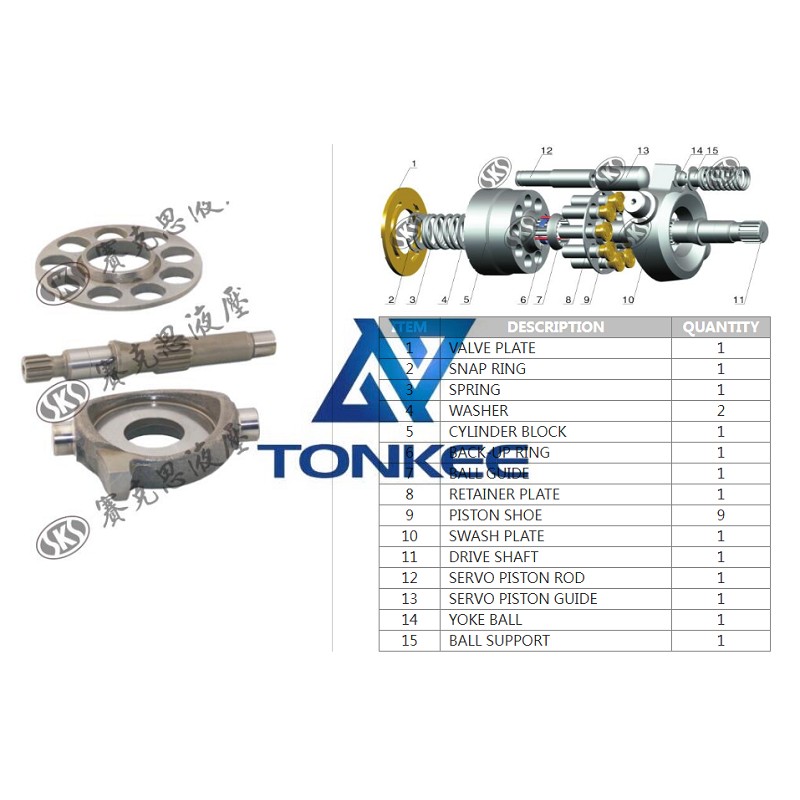

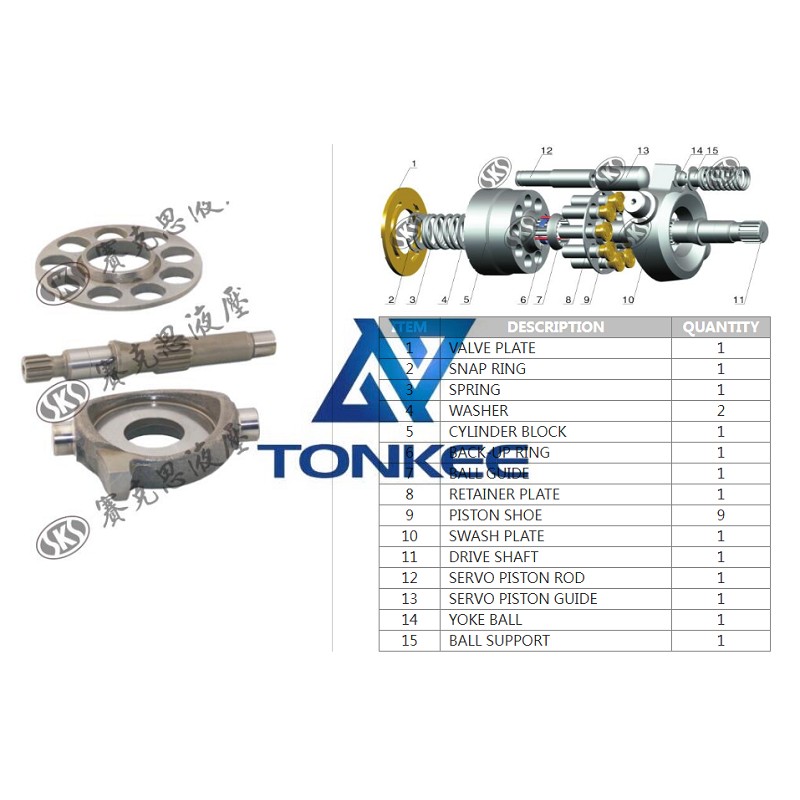

The PVQ50 SERVO PISTON GUIDE is specifically engineered to work with the PVQ series of hydraulic pumps.

It acts as a guide for the servo piston, ensuring smooth and accurate movement within the pump. The guide is made from high-quality materials to withstand the demanding conditions of hydraulic systems, providing durability and longevity.

One of the key features of the PVQ50 SERVO PISTON GUIDE is its precision design. It is meticulously crafted to exacting tolerances, allowing for minimal clearance between the piston and the guide. This tight fit ensures efficient power transfer and minimizes energy loss, resulting in improved overall pump performance.

The guide incorporates advanced sealing technology to prevent leakage and maintain optimal hydraulic pressure. It features high-quality seals that are resistant to wear and tear, ensuring reliable operation over an extended period. This design also contributes to the overall efficiency of the hydraulic system by reducing fluid losses and minimizing maintenance requirements.

Additionally, the PVQ50 SERVO PISTON GUIDE is engineered to provide enhanced control and responsiveness. It enables precise positioning of the servo piston, allowing for accurate modulation of fluid flow and pressure. This level of control is crucial in applications where fine-tuning of hydraulic parameters is necessary, such as in industrial machinery and heavy equipment.

Furthermore, the PVQ50 SERVO PISTON GUIDE is designed to be compatible with various hydraulic fluids, including mineral oils and synthetic fluids.

This versatility allows it to be utilized in a wide range of hydraulic systems, offering flexibility to system designers and end-users.

In terms of installation and maintenance, the PVQ50 SERVO PISTON GUIDE is designed for easy integration into hydraulic pump assemblies. Its dimensions and mounting configurations are standardized, ensuring compatibility with the PVQ series pumps. Routine maintenance involves inspecting and replacing worn seals, which can be easily accessed without the need for extensive disassembly.

English

English português

português Русский язык

Русский язык