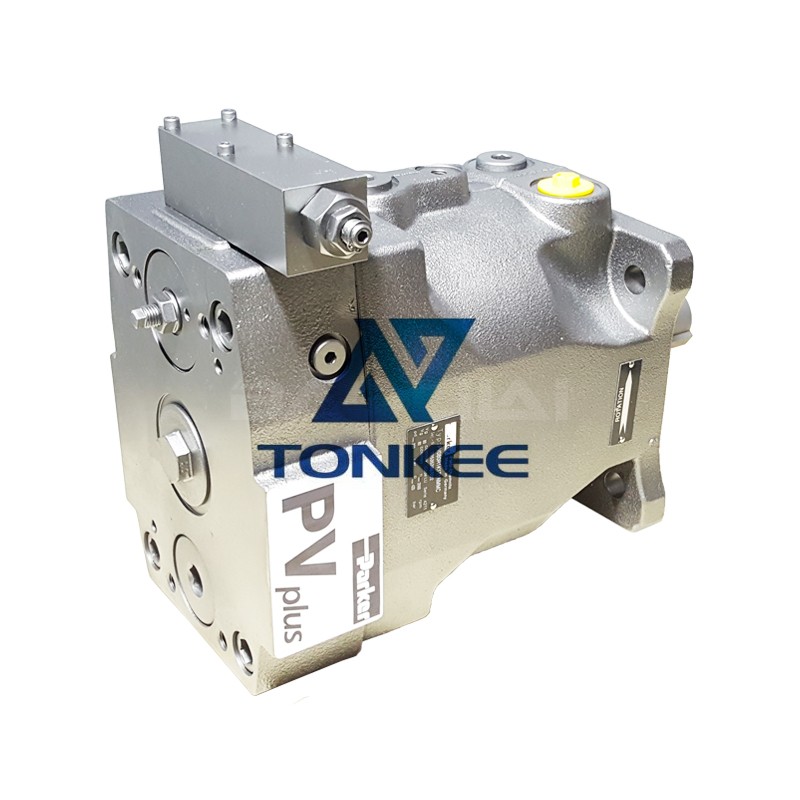

Pump Model and Series: The first and most crucial specification is the pump model and series.

Parker offers different models and series within the PV Series, each with unique features and specifications. It is essential to identify the exact model and series of your pump to ensure compatibility with the replacement parts. This information can usually be found on the pump nameplate or documentation.

Displacement: The displacement of a hydraulic pump refers to the volume of fluid it can deliver per revolution or stroke. It is typically measured in cubic inches or milliliters. Knowing the displacement of your original pump is vital when selecting replacement parts. Matching the displacement ensures that the replacement pump will provide the same flow rate and performance as the original.

Mounting Type: The PV Series pumps come in various mounting configurations, such as flange, foot, or face mount. The mounting type determines how the pump is attached to the power source, such as an electric motor or an engine. When searching for replacement parts, make sure to choose the correct mounting type to ensure proper installation and alignment.

Shaft Type and Size: The shaft of the hydraulic pump connects to the power source and transmits rotational motion. It is important to determine the shaft type (keyed, splined, tapered, etc.) and size (diameter and length) of your original pump to find compatible replacement parts. Matching the shaft specifications ensures that the replacement pump will fit seamlessly into your hydraulic system.

Flow and Pressure Ratings: Hydraulic pumps have specific flow and pressure ratings that determine their operating capabilities. The flow rating refers to the maximum volume of fluid the pump can deliver, usually measured in gallons per minute (GPM) or liters per minute (LPM). The pressure rating indicates the maximum pressure the pump can handle, typically measured in pounds per square inch (PSI) or bar. Ensure that the replacement parts you select have similar or higher flow and pressure ratings than your original pump to avoid any performance issues.

Seal Type and Material: Seals are essential components of hydraulic pumps as they prevent fluid leakage and maintain system efficiency.

The PV Series pumps may use different types of seals, such as O-rings or lip seals. Additionally, the material of the seals can vary, including rubber, polyurethane, or Teflon. Identifying the seal type and material used in your pump is crucial when sourcing replacement parts to ensure proper sealing and longevity.

Compatibility with Fluid: Hydraulic systems use different types of fluids, such as mineral oil, synthetic oil, or water-glycol mixtures. It is important to select replacement parts that are compatible with the fluid used in your system. Consider factors such as fluid viscosity, temperature range, and chemical compatibility to ensure optimal performance and longevity of the replacement parts.

English

English português

português Русский язык

Русский язык