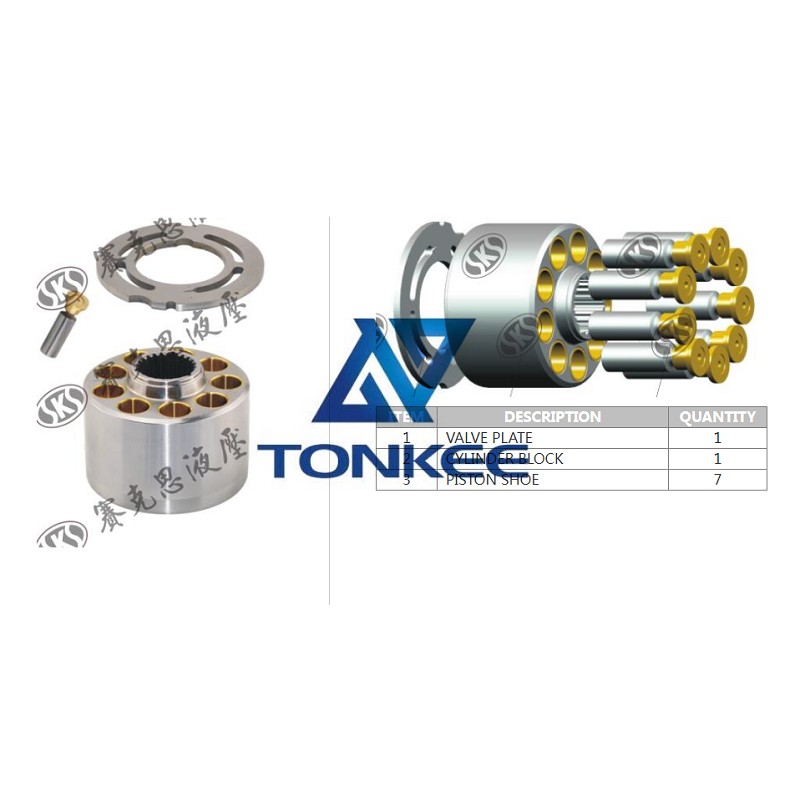

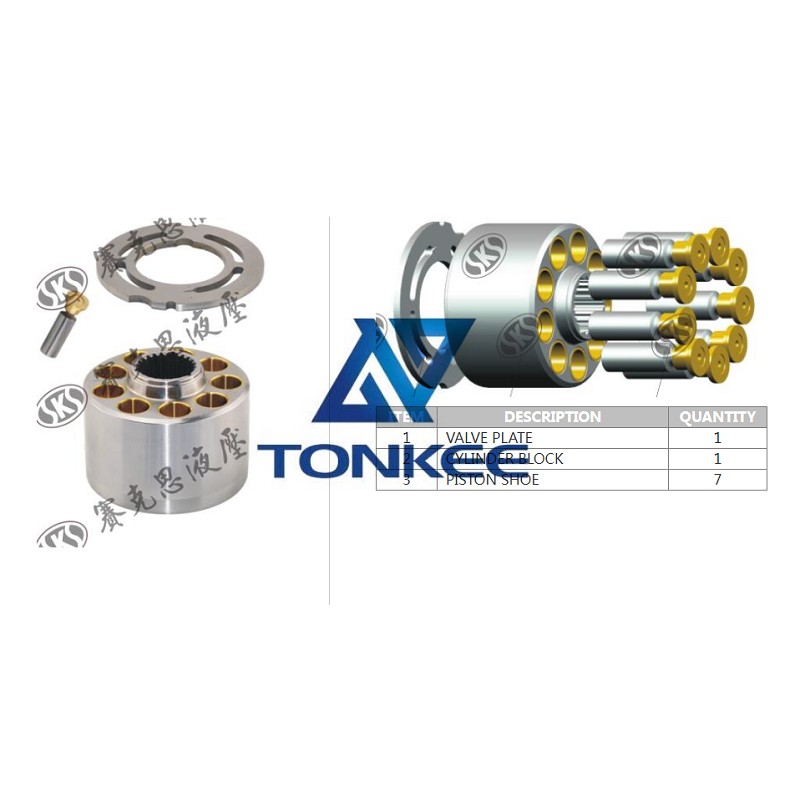

The MPR63 valve plate is precision-engineered using durable materials to ensure longevity and efficient operation.

It is typically made from high-strength metals, such as steel or aluminum alloy, that can withstand the high pressures and forces associated with hydraulic systems. The valve plate undergoes rigorous quality control measures during the manufacturing process to meet strict industry standards and specifications.

This valve plate features a complex design consisting of multiple channels, ports, and valves. It acts as a control mechanism, directing the flow of hydraulic fluid to different sections of the pump, such as the cylinder, reservoir, and various hydraulic components. By opening and closing specific valves, the valve plate regulates the flow rate and pressure of the hydraulic fluid, allowing for precise control and smooth operation of the hydraulic system.

The MPR63 valve plate is designed to be compatible with a wide range of hydraulic pumps, including vane pumps, piston pumps, and gear pumps. It is available in various sizes and configurations to accommodate different pump models and system requirements. Proper sizing and compatibility are essential to ensure optimal performance and prevent any issues or malfunctions within the hydraulic system.

To install the MPR63 valve plate, it is important to follow the manufacturer's instructions and guidelines.

The valve plate is typically placed between the pump housing and the cylinder block, forming a sealed chamber. Careful attention should be given to the alignment and positioning of the valve plate to ensure proper functionality and prevent leakage.

Regular maintenance and inspection are crucial to keep the MPR63 valve plate in optimal condition. This includes periodic cleaning, lubrication, and checking for any signs of wear or damage. Any worn-out or damaged valve plates should be promptly replaced to avoid potential system failures and maintain the overall efficiency of the hydraulic pump.

English

English português

português Русский язык

Русский язык