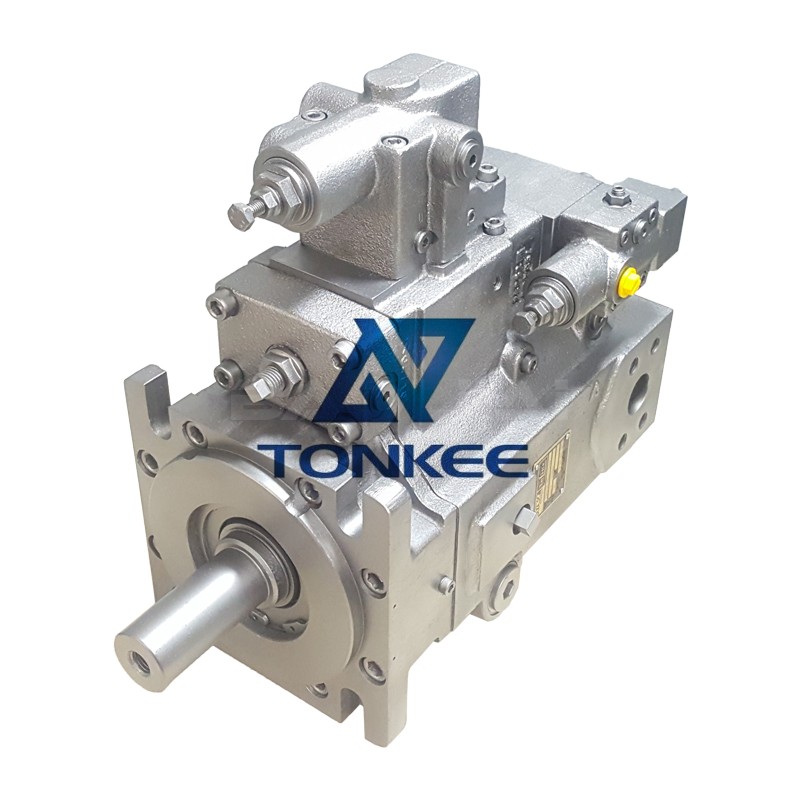

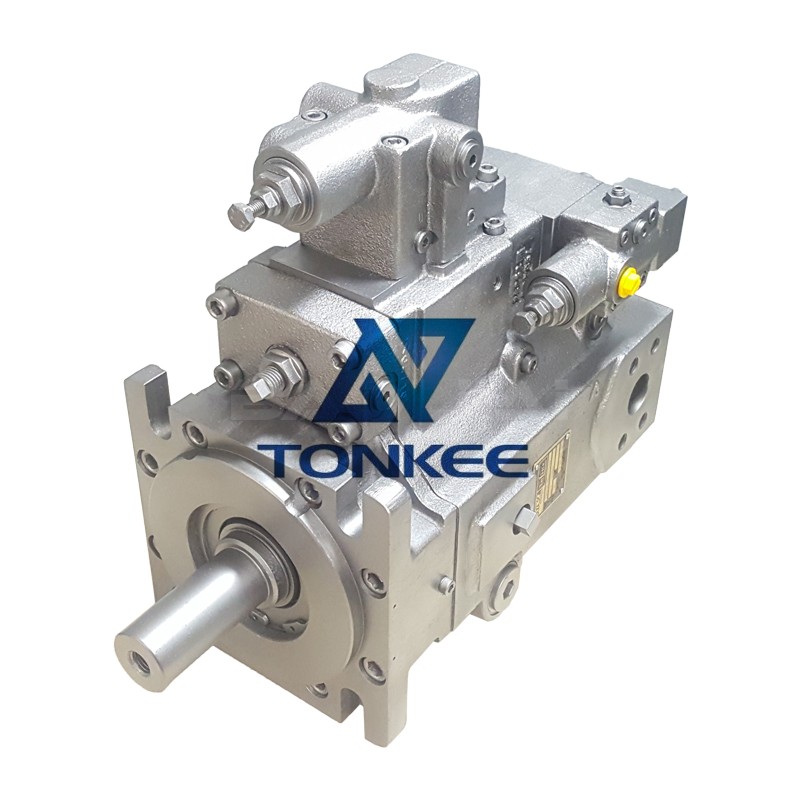

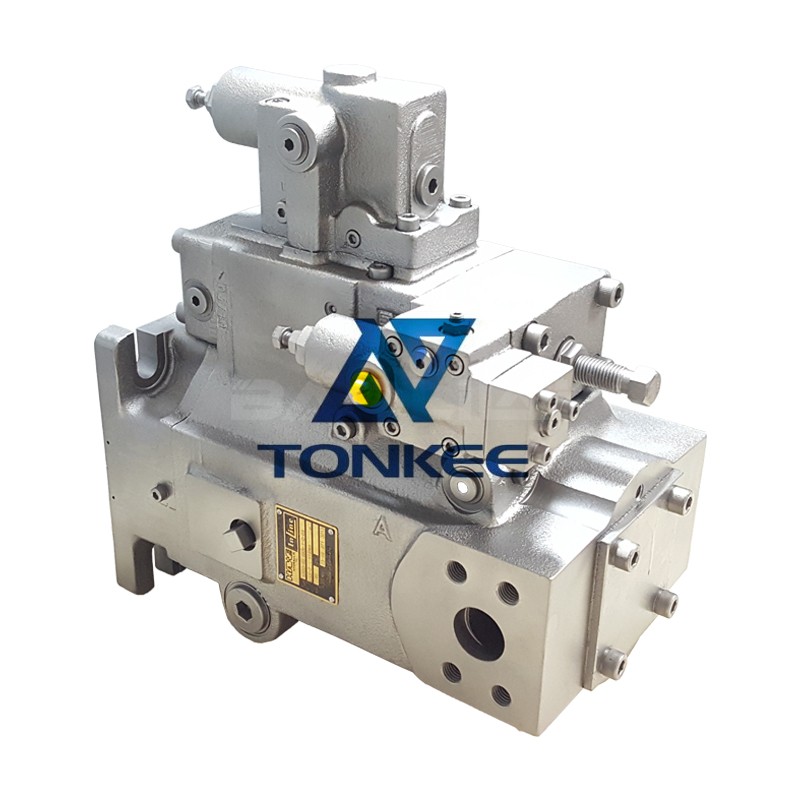

The HAWE V30D series pump consists of several vital components that may require replacement over time.

These components include the pump housing, pistons, valve plates, port plates, swash plates, bearings, seals, and gaskets. Each part plays a critical role in the overall functioning of the hydraulic pump, and sourcing the right replacement parts is essential for maintaining efficiency and reliability.

One of the primary considerations when choosing replacement parts is the compatibility with the specific model and series of the HAWE V30D pump. It is crucial to ensure that the replacement parts match the exact specifications and dimensions of the original components. This ensures a proper fit and prevents any issues that could arise from using incompatible parts. Therefore, it is advisable to consult the manufacturer's documentation or seek expert advice to identify the correct replacement parts for the specific model within the V30D series.

Another important factor to consider is the quality and durability of the replacement parts. Since the hydraulic pump operates under high pressures and heavy loads, it is essential to choose parts that are manufactured with high-quality materials and precision engineering. Opting for genuine OEM (Original Equipment Manufacturer) parts or reputable aftermarket parts from trusted suppliers can help guarantee the longevity and reliability of the hydraulic pump.

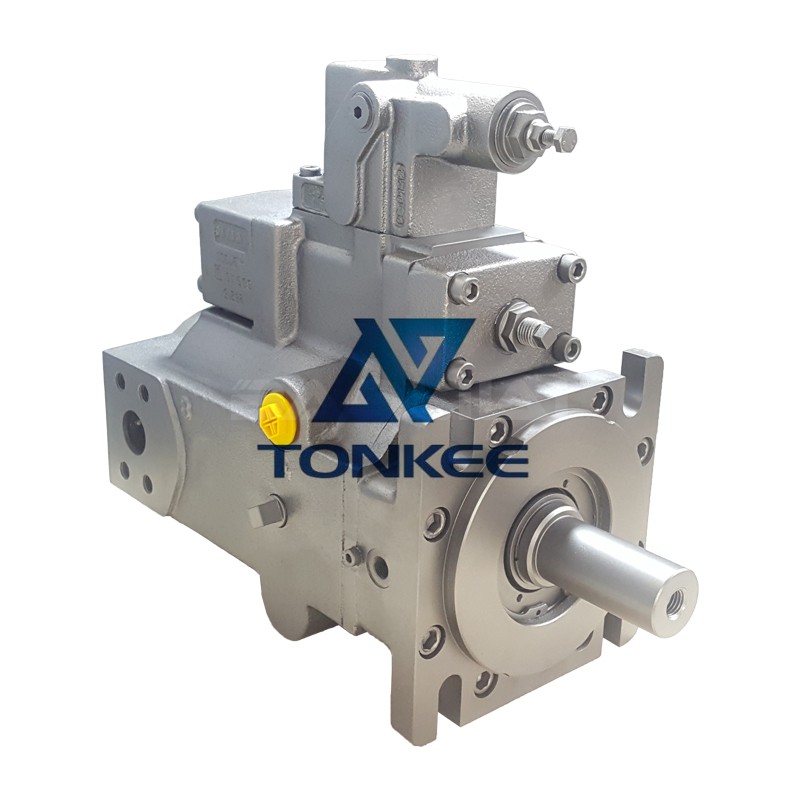

Seals and gaskets are critical components that require careful attention during the replacement process. These parts ensure a leak-free operation and prevent fluid contamination. When selecting replacement seals and gaskets, it is crucial to consider factors such as material compatibility, operating temperature, pressure rating, and the specific location within the pump where they will be installed. Proper installation techniques, such as ensuring correct alignment and lubrication, are also essential for achieving optimal performance and sealing efficiency.

Bearings are another vital component that may require replacement.

When choosing replacement bearings, factors such as load capacity, speed rating, and lubrication requirements should be taken into account. It is advisable to select high-quality bearings from reputable manufacturers to ensure smooth operation and minimize the risk of premature failure.

Maintenance and regular inspection of the hydraulic pump are crucial for identifying potential replacement needs in a timely manner. This allows for proactive planning and sourcing of the necessary replacement parts, reducing downtime and maximizing the lifespan of the hydraulic system.

English

English português

português Русский язык

Русский язык